FOPIPE: PIPELINE INTEGRITY MONITORING

![]() Prevention of environmental impact

Prevention of environmental impact

![]() Reduction of human risks

Reduction of human risks

![]() Increase in profitability

Increase in profitability

![]()

![]()

![]()

![]()

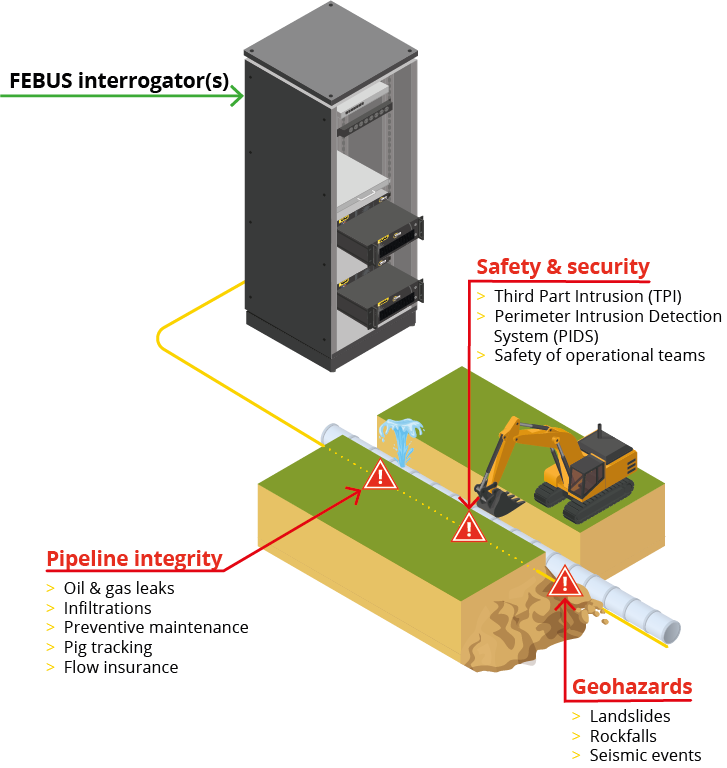

An onshore or offshore pipe spans tens or even hundreds of kilometers and can be exposed to numerous damages of human or natural origin. To detect these risks, define them and provide the most appropriate response, FEBUS Optics' solution enables continuous and end-to-end monitoring throughout the installation to:

- monitor the integrity of the pipeline

- anticipate, detect, locate, and identify threats and potential damages.

FOPipe: FEBUS Optics' pipeline monitoring solution

PIPELINE MONITORING USING DISTRIBUTED FIBER OPTIC SENSING

FOPipe is FEBUS Optics' complete and easy to implement solution for ensuring continuous real-time monitoring of pipeline integrity, whether onshore or offshore.

Based on our various distributed fiber optic sensing patented technologies, it relies on the use of our interrogators:

- Distributed Acoustic Sensing (DAS, acoustic data) with the FEBUS A1

- Distributed Temperature and Strain Sensing (DTSS, temperature and strain data) through the FEBUS G1-R.

The combination of the performance of our measurement systems, our embedded software solution FOPipe Suite, and the power of our detection and classification algorithms allows:

- maximizing the availability and durability of infrastructure

- optimizing production and monitoring costs

- increasing the safety of operational teams

- preventing environmental risks.

| Real-time detection and information | Precise, reliable, and repeatable measurement | Accurate localization of the alerts | Intelligent doubt removal of alerts |

WHY CHOOSE FEBUS OPTICS FOR PIPELINE INTEGRITY MONITORING?

| High detection sensitivity (DAS and DTS technologies) | All threats are detected, irrelevant alerts are ignored, and production losses are limited. | |

| Real-time monitoring | Swift responses are provided, environmental and human risks are prevented. | |

|

Precise localization Qualification of alerts |

Maintenance costs are optimized. | |

|

Continuous monitoring |

A check that the problem is resolved is made or a new intervention is planned. | |

|

Long range |

Long distances are monitored, optimizing CAPEX and OPEX. |

| Alerting software communication via standard protocols | Our solution is fully compatible with any VMS or monitoring system. | |

|

Maintenance contract |

The availability of FEBUS devices is optimized. | |

|

FEBUS Optics support |

The project runs in an atmosphere of serenity. |

|

| ISO 9001 certification | The quality of our products, services and support is recognized. | |

| Possibility to test our solution at the Test Center (CESG) | Our solution is validated to meet the needs and specifics of your project. |

FEBUS PIPELINE MONITORING APPLICATIONS

MONITORING WASTEWATER PIPELINES

FOPipe, the distributed fiber optic sensing solution for pipeline monitoring, enables real-time detection of any leaks or infiltrations in the sewage pipeline network. An alert indicating the precise location of the event is generated. Risks of pathogen leaks and financial losses are limited.

MONITORING WATER NETWORK

Swift detection of water pipelines failures, such as pipe leaks or infiltrations, is crucial to optimize the distribution of this vital resource and reduce health risks. FEBUS systems provide continuous measurement for event detection and real-time alert generation along the entire network.

PIPELINE LEAK DETECTION

FEBUS Optics' pipeline monitoring solution conducts continuous measurements, providing real-time accurate data on the integrity of structures. Any leakage is quickly detected for the optimal implementation of an appropriate response.

OIL AND GAS PIPELINE MONITORING

In the oil and gas industry, pipelines are critical infrastructures susceptible to leaks, damages from third-party intrusions, and fluid theft. Moreover, any intervention near or on a pipeline poses risks to the involved teams. The FEBUS complete solution for failure detection and alerting helps mitigate these risks.

OTHER FEBUS APPLICATIONS FOR PIPELINE MONITORING

Operational event detection and preventive maintenance

During the operation of a pipeline, so-called "operational" events can occur, jeopardizing the structure's integrity and posing a danger to operational teams. It is crucial to monitor these events. FEBUS technology detects various types of events, including:

- wear and tear on mechanized equipment (such as pump, motor, generator),

- water leakage,

- structural alteration caused, for example, by the appearance of cracks,

- wear of valves due to repetitive opening/closing,

- formation of bubbles and movements of pockets in the pipe,

- pig tracking.

The "pig" is a scraper piston inserted into a pipeline to clean it as deposits can form on the walls, and potentially affect production. This "pigging" operation deserves monitoring.

FEBUS Optics' distributed fiber optic sensing technology and the FEBUS A1 (DAS - Distributed Acoustic Sensing) allow real-time tracking of the "pig" in the pipeline to:

- determine the position and speed of the scraper piston

- anticipate the tool's arrival at the end of the structure

- control the flow of oil or gas and ensure the "pig" is not damaged

- avoid uncontrolled releases at the end of the infrastructure

- reduce personnal along the pipeline and ensure operational safety.

By tracking the progress of the "pig" in the structure, the risks of accidents and damages are minimized, optimizing production.

Pipeline integrity monitoring at the CESG

Qualified since 2022 by major international operators, the CESG (Test Center Sophie Germain) allows for semi-industrial scale tests of pipeline integrity monitoring:

- leak detection

- intrusion detection

- detection of ground movements.

Our pipeline is 22 meters long, equipped with electrovalves to generate pressurized leaks in controlled flow and orientation. Fiber optic cables are arranged in a trench in different configurations to find the best compromise for detecting an event as quickly as possible.

A distribution plate installed on hydraulic jacks can lift up to 30 tons to deform the structure and produce ground movements.

To simulate gas and hydrocarbon leaks, FEBUS Optics equipment is CE certified and can:

- generate air leaks (50 bars)

- hot water leaks (60 °C, 20 bars)

- at different angles (from 0 to 360 °)

- and different diameters (from 1 to 6 millimeters).

Liquid leak on a pipe at the Test Center (CESG)

To replicate on-site conditions, FEBUS Optics technical experts conduct leakage tests at industrial distances at the Test Center using fiber optic over lengths of over 100 kilometers.

FEBUS teams offer real-world tests and demonstrations.

We prepare our pipeline (or the client's) and fiber optic cables according to configurations specifically adapted to the project's characteristics (one or more fiber optic cables, wound around the pipeline or laid freely against the structure, buried or submerged pipeline, with or without thermal insulation, etc).

The CESG is also a training facility.

FEBUS Optics teams present our solutions and train our clients in using our interrogators, combining practical and theoretical aspects in our meeting room.

Training, and theoretical and practical demonstrations

IMPLEMENTATION AND FEBUS OPTICS SERVICE

The FEBUS Optics solution is effective on an existing fiber network. However, we bring our expertise to optimize the choice of fiber optic cable and its position on the pipeline.

We deploy our pipeline monitoring solution and configure the system on-site or remotely.

Then, we conduct follow-ups. After an initially defined operating period with the client, FEBUS experts check the proper functioning of the system and optimize it.

Then they provide training and support throughout the project.

FEBUS Optics also offers an annual maintenance contract, a warranty extension beyond 3 years and continuity of service.

Are you looking for a pipeline prevention solution against potential damages?

Do you have any questions?